Best Ball Screw for Sale Options for Your Projects?

In today's manufacturing landscape, finding the right "ball screw for sale" can be a daunting task. Industry expert Dr. Emily Carter once stated, “Choosing the right ball screw can significantly enhance machine precision.” With numerous options available, making an informed decision is crucial for project success.

Balancing quality and cost is a challenge. Not all ball screws marketed are created equal. Some may seem affordable but may compromise performance. It’s essential to assess the specifications that align with your project needs.

Real-world applications of ball screws highlight their importance. For example, in CNC machinery, the right ball screw reduces wear and increases accuracy. Yet, without thorough research, mistakes can be costly. A focus on quality over price usually yields better results in the long run.

Understanding the Basics of Ball Screws for Your Projects

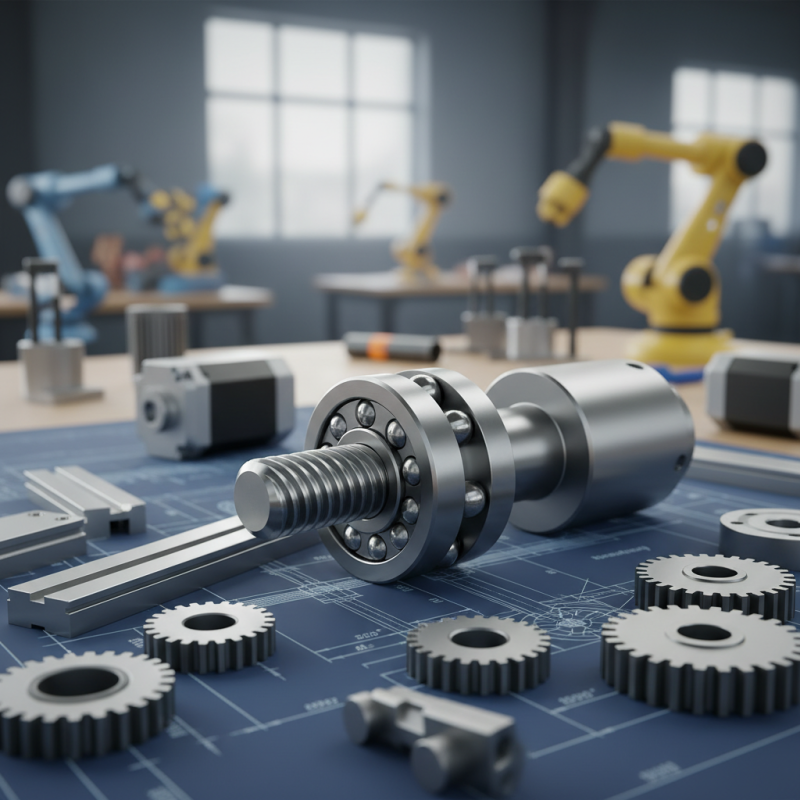

When considering ball screws for your projects, it's crucial to grasp their fundamental principles. Ball screws convert rotational motion into linear motion. They consist of a threaded shaft and a ball nut. Balls circulate between the nut and the screw, reducing friction significantly. This design enhances efficiency and offers precise control.

Choosing the right ball screw can be tricky. Various factors impact your selection, including load capacity, speed, and accuracy. Additionally, the installation environment plays a role. Factors such as vibration and dust can affect performance. It's essential to assess your project's specific needs carefully. Testing can reveal preferences that theoretical knowledge does not cover.

Common mistakes occur during installation. Misalignment can lead to wear and decreased lifespan. Ensuring proper lubrication is necessary too. Over-lubrication and under-lubrication both have consequences. Finding a balance can take time and experimentation. So, be prepared for some trial and error. Understanding these basic concepts will help you make informed choices.

Types of Ball Screws Available for Sale in the Market

Ball screws are essential components in many engineering projects. They are designed for converting rotary motion into linear motion with high efficiency. Several types of ball screws are available on the market, each suited for different applications.

Standard ball screws are widely used. They offer a good balance of performance and cost. Precision ball screws provide higher accuracy. These are essential in applications requiring exact positioning. There are also miniature ball screws, perfect for compact spaces. They may be small but still deliver significant load capacities.

Another type is rolled ball screws. They are created through a rolling process, making them cost-effective. Preloaded ball screws are available too. They minimize backlash, ensuring precise movements. Choosing the right type can be complex. Users often face challenges in understanding the specifications needed for their projects. It's important to analyze your specific requirements carefully.

Factors to Consider When Choosing a Ball Screw

When selecting a ball screw for your projects, consider several factors that can impact performance. The load capacity is crucial. It defines how much force your screw can handle. Check the specifications carefully. A mismatch here could lead to failure.

Speed is another factor. Different applications require different speeds. Too fast can cause overheating. Too slow might affect efficiency. Aim for a balance that suits your needs.

Tip: Always double-check the dimensions. An incorrect size can lead to installation issues. Remember, precision is key. Also, consider the material of the screw. Steel is common, but sometimes other materials offer better longevity.

Don’t overlook the environmental conditions. Ball screws may operate in harsh environments. Dust, moisture, and temperature extremes can all play a role in performance. Choosing a screw that can withstand these conditions is critical. Reflect on your project’s specific needs before making a final decision.

Best Ball Screw for Sale Options for Your Projects

| Screw Diameter (mm) | Lead (mm) | Accuracy Class | Load Capacity (N) | Material | Price ($) |

|---|---|---|---|---|---|

| 16 | 5 | C7 | 1500 | Steel | 120 |

| 20 | 10 | C5 | 2500 | Carbon Steel | 200 |

| 25 | 12 | C3 | 4000 | Stainless Steel | 350 |

| 30 | 16 | C7 | 5000 | Aluminum | 450 |

| 35 | 20 | C5 | 7500 | Alloy Steel | 600 |

Top Suppliers for Quality Ball Screws

When it comes to sourcing quality ball screws, it's essential to identify suppliers known for precision and reliability. Ball screws are critical in various applications, including robotics and CNC machinery. According to industry reports, the global ball screw market size was valued at over $3 billion in 2022 and is expected to grow significantly. This indicates a rising demand for high-quality screws that cater to precision motion control.

Top suppliers often prioritize innovation in manufacturing techniques. They may use advanced materials to enhance durability or improve load capacity. However, not all suppliers deliver the same level of quality. Some may cut corners, leading to early wear or failure in applications. Industry data suggests that about 15% of ball screws sold do not meet performance standards. This raises concerns for engineers and project managers when selecting components.

Moreover, it's vital to consider customer service and support when choosing a supplier. Manufacturers that provide extensive documentation and after-sale assistance can significantly affect project success. Technical challenges may arise, and having a reliable point of contact can be invaluable. Companies could benefit from collaborative partnerships with suppliers, ensuring they have access to the latest improvements and industry advancements. Quality ball screws can help optimize performance, but not all sellers prioritize this crucial aspect.

Cost Analysis of Various Ball Screw Options for Projects

When considering ball screws for your projects, cost analysis becomes crucial. Various options exist, each with distinct pricing ranges. Lower-cost ball screws may attract attention, but they often compromise on durability and precision. This can lead to costly repairs or replacements in the long run.

It's essential to assess your project's specific needs before making a purchase. For instance, high-load applications require more robust options. These may have a higher initial cost but offer greater reliability. Sometimes, what's cheap upfront can turn expensive later.

Another factor is the sourcing of your components. Local suppliers can reduce shipping costs and lead times. However, they might offer limited options. On the other hand, international suppliers provide a broader selection. But additional import fees can inflate the overall cost. Evaluating the trade-offs here requires careful thought. There may not be one perfect choice; each option has risks and benefits.